As environmental awareness continues to grow, sustainable and eco-friendly materials have become increasingly popular in the construction and design industry.

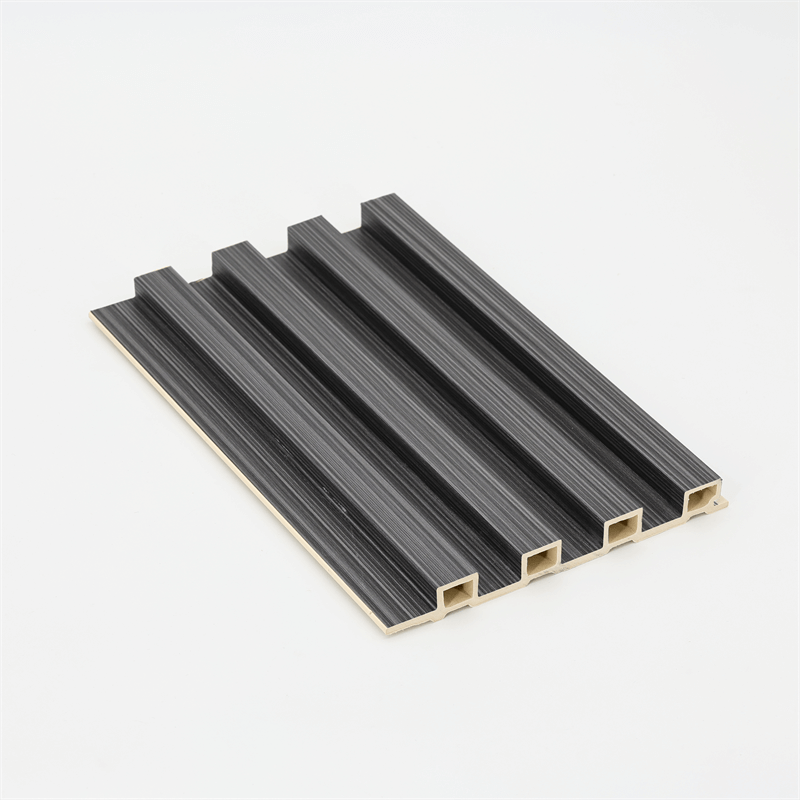

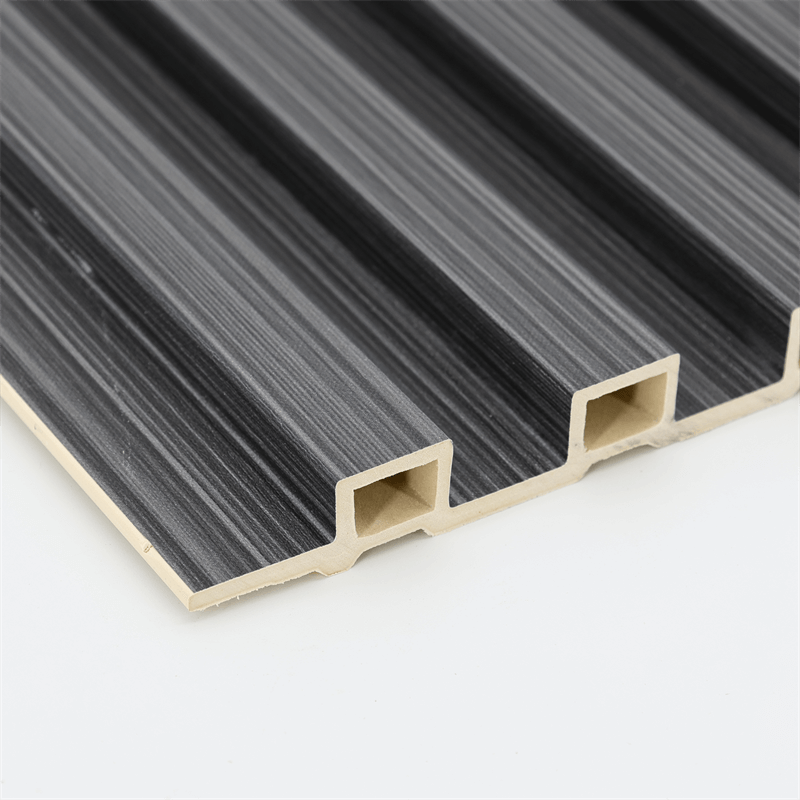

Wall panel WPC (Wood Plastic Composite) is one such material that offers numerous environmental benefits.

In this article, we will explore the eco-friendly aspects of wall panel WPC, including its manufacturing process, recyclability, energy efficiency, and impact on natural resources.

By understanding these environmental benefits, manufacturers, suppliers, and consumers can make informed choices and contribute to a greener future.

I. Sustainable Manufacturing Process

Use of Recycled Materials Wall panel WPC is typically manufactured using a combination of wood fibers and thermoplastic resins.

One of the key environmental advantages of WPC is the utilization of recycled materials.

The wood fibers in WPC are often sourced from post-industrial wood waste or reclaimed wood, diverting these materials from landfills and reducing the demand for virgin wood.

Reduced Waste Generation The manufacturing process of wall panel WPC is designed to minimize waste generation.

Unlike traditional wood processing, where substantial amounts of sawdust and other byproducts are discarded, WPC production optimizes the use of raw materials, resulting in minimal waste.

Any waste generated during the manufacturing process can often be recycled or reused, further reducing its environmental impact.

II. Recyclability and Reusability

Recyclable Material One of the significant environmental benefits of wall panel WPC is its recyclability.

At the end of its lifecycle, WPC can be recycled and transformed into new products or used as a raw material for other applications.

This reduces the amount of waste sent to landfills and helps conserve natural resources.

Manufacturers and suppliers can play a crucial role in facilitating the recycling process by establishing recycling programs or partnering with recycling facilities.

Reusability in Other Applications In addition to recyclability, wall panel WPC also offers reusability in other construction applications.

For example, WPC panels that are removed from a building during renovation or demolition can be repurposed in various ways, such as outdoor decking, furniture, or landscaping elements.

This extends the lifespan of the material and reduces the need for new production, resulting in further environmental benefits.

III. Energy Efficiency and Reduced Emissions

Energy-Efficient Manufacturing Compared to the production of traditional materials like concrete or metal, the manufacturing process of wall panel WPC is relatively energy-efficient.

The use of recycled materials and streamlined production techniques helps minimize energy consumption during manufacturing.

This translates into reduced greenhouse gas emissions and a smaller carbon footprint.

Lower VOC Emissions Volatile Organic Compounds (VOCs) are chemicals that can be emitted from certain building materials and negatively impact indoor air quality.

Traditional materials like paint and adhesives often contain VOCs, but wall panel WPC is typically manufactured without the use of these harmful substances.

Choosing WPC panels for interior applications can contribute to healthier indoor environments by minimizing VOC emissions.

IV. Conservation of Natural Resources

Reduced Demand for Virgin Wood The use of wall panel WPC helps reduce the demand for virgin wood, which is typically sourced from forests.

By utilizing recycled wood fibers and reclaimed wood, WPC panels contribute to the conservation of forests and promote responsible forestry practices.

This helps protect biodiversity, maintain ecosystems, and preserve natural habitats.

Water and Chemical Conservation The manufacturing process of wall panel WPC requires less water and chemicals compared to traditional wood processing or other materials like concrete or metal.

By reducing water consumption and minimizing chemical usage, WPC panels help conserve these valuable resources and minimize the environmental impact associated with their extraction and production.

Wall panel WPC offers a range of environmental benefits that make it an eco-friendly and sustainable choice for construction and design projects.

Its sustainable manufacturing process, recyclability, reusability, energy efficiency, and contribution to natural resource conservation make it a greener alternative to traditional materials.

Manufacturers, suppliers, and consumers can play a significant role in promoting the use of wall panel WPC and contributing to a more sustainable future.

By prioritizing eco-friendly materials like WPC, we can create a built environment that is both aesthetically pleasing and environmentally responsible.